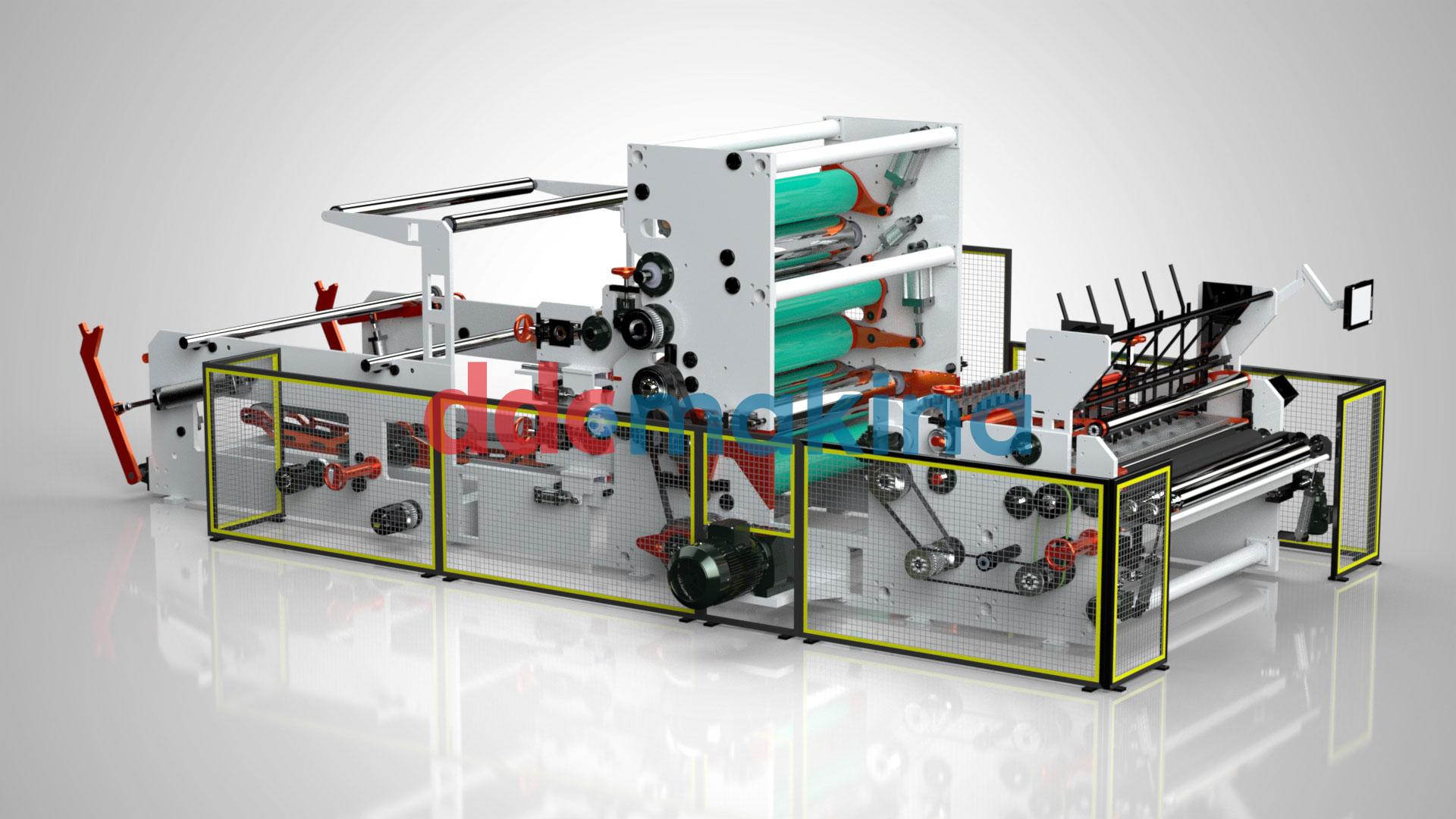

Automatic Dual Rewinding Machine

Automatic Dual Toilet Paper and Kitchen Towel Wrapping Machine is an industrial machine that can wrap products with two different embossing techniques in a single machine and thus meet the demands of different customer groups.

Automatic Dual Toilet Paper and Kitchen Towel Winding Machine has an important place in the processes of winding the main bobbins into rolls by passing through the embossing and lamination unit. This machine, with its double embossing and lamination system feature, winds with two different embossing techniques at high speed.

Offering a continuous and effective solution in paper production, this machine plays an indispensable role in modern production facilities.

What is Automatic Dual Toilet Paper and Kitchen Towel Winding Machine?

Automatic Dual Toilet Paper and Kitchen Towel Wrapping Machine is an industrial machine that can wrap products with two different embossing techniques in a single machine and thus meet the demands of different customer groups.

What are the Features of Automatic Dual Toilet Paper and Kitchen Towel Rewinding Machine?

The main features of this machine include:

- Double Embossing Technique: Ability to wrap products with two different embossing patterns.

- High Efficiency: Fast and uninterrupted production capacity.

- Flexible Production Options: Ability to process paper of different sizes and thicknesses.

- User Friendly Design: Easy operation and adjustable features.

| MACHINE WIDTH | MIN 1350 – MAX 2800 MM |

| MACHINE SPEED | MAX 200 MT/MIN |

| MAX ROLL REWINDING DIAMETER | MIN 90 – MAX 300MM |

| EMBOSSING GROUP | POINT TO POINT AND DAZZLE |

| PERFORATION CONTROL | SERVO CONTROL |

| REWINDING GROUP | AUTOMATIC |

| TAIL CUT AND SEALING | AUTOMATIC |

| PRODUCT PLY | 1-4 |

| EMBOSSING, LAMINATION, JOINTING ROLLER | HYDRAULIC |

| BOBBIN QUANTITY | 1-2 |

Where is Automatic Dual Toilet Paper and Kitchen Towel Winding Machine Used?

Automatic Dual Toilet Paper and Kitchen Towel Rewinding Machine is generally used in large and medium-sized paper production and converting plants.

How should the maintenance of Automatic Dual Toilet Paper and Kitchen Towel Winding Machine be?

Maintenance of the Automatic Dual Toilet Paper and Kitchen Towel Rewinder is important to ensure the long life and efficient operation of the machine. The maintenance routine should include the following:

- Regular Cleaning and Lubrication: Necessary for proper operation of the machine.

- Control of Mechanical Parts: Regular inspection of moving parts.

- Inspection of Electronic Systems: Regular checking of the machine’s electronic systems.

Automatic Winder (Dual) For Paper Roll Types of Products

- Household Toilet Paper

- Self-pull Toilet Paper

- Jumbo Toilet Paper

- Kitchen Towel

- Internal Pull Towel

- Industrial Towel

- Examination Table Cloth

Conclusion

Automatic Dual Toilet Paper and Kitchen Towel Winding Machine is an industrial machine designed for high speed and efficient paper roll winding and production, producing products with double pattern technique. The vertical design of embossing and lamination rollers is important in terms of space saving in the factory. This machine plays an important role by saving time and cost, especially in large-scale production facilities. With regular maintenance and proper use, this machine can serve effectively for many years.