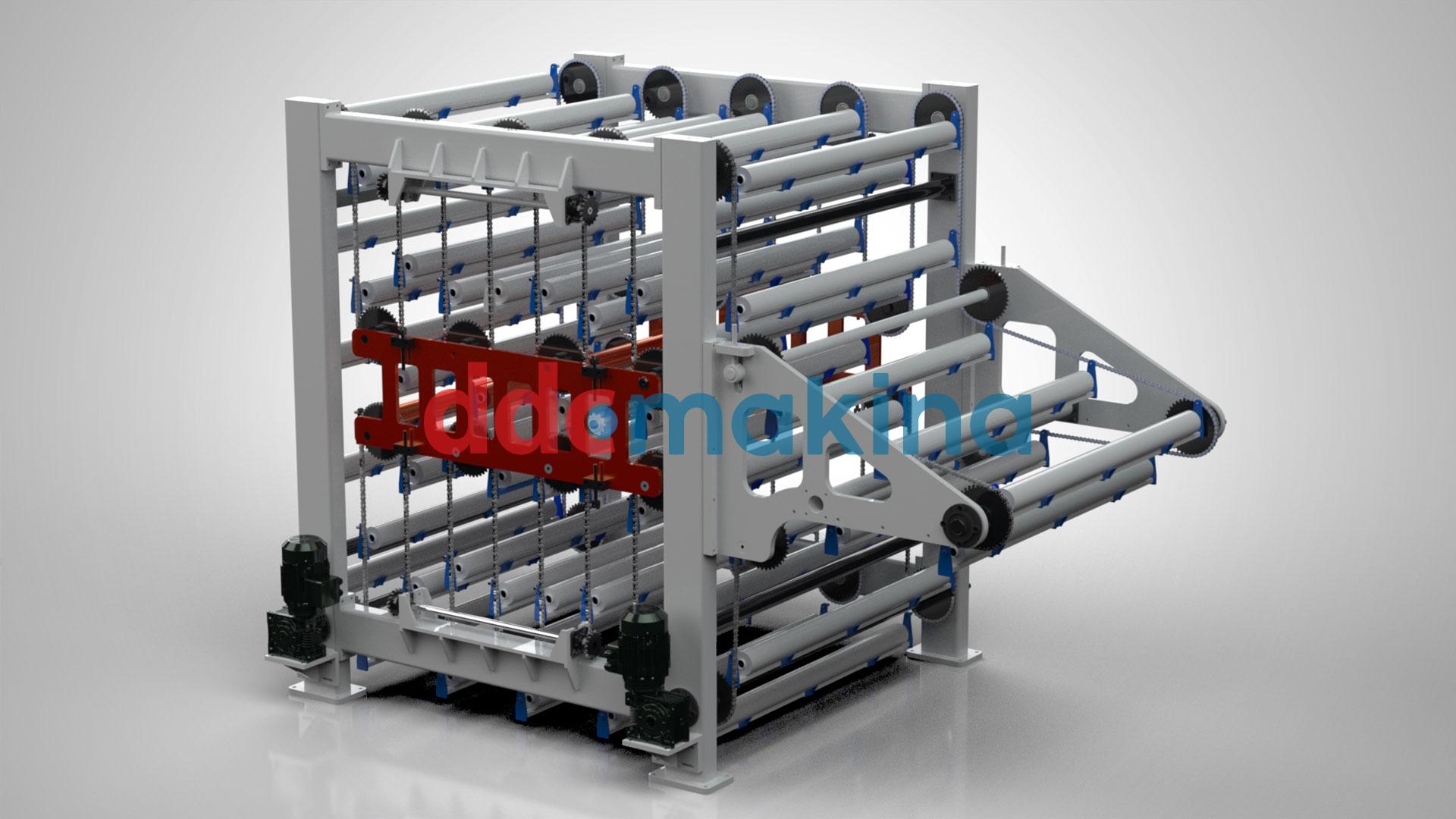

Toilet Paper Accumulator

The Roll/Log Accumulator is a device that transfers the produced rolls of toilet paper or kitchen towels to the next unit and regulates the flow in the production process.

Accumulator, the transfer machine is a device that plays an important role in the production processes of toilet paper and kitchen towel rolls, increasing the efficiency of production lines. This equipment automates the storage, sorting and dispatching of rolls, ensuring that the production process is uninterrupted and orderly.

This device which is widely used in modern toilet paper production facilities, significantly increases the efficiency of the production line and product quality.

What is an Accumulator in Toilet Paper production?

The Roll/Log Accumulator is a device that transfers the produced rolls of toilet paper or kitchen towels to the next unit and regulates the flow in the production process.

This accumulator is designed to prevent possible disruptions in the production line and to ensure a continuous production flow. It facilitates the organized processing and packaging of the rolls in the production process and allows the glue to dry before the rolls are cut to the desired size. This directly affects the product quality during the cutting process.

What are the Accumulator Features?

The prominent features of this device are as follows:

- High Storage Capacity: Ability to store large quantities of toilet paper rolls.

- Automatic Sorting and Dispatching: Organized and efficient sorting and dispatching of rolls.

- Flexible Adaptability: Adaptability to production lines of different sizes and capacities.

| Basket Capacity | 90-300 MM Product Diameter |

| Width | Max 2800 MM |

| Number Of Baskets | 70-360 |

| Working Type | By Backup Transfer |

Where is Accumulator Used?

Toilet Paper Accumulator is generally used in large-scale toilet paper production plants. It is especially necessary to ensure efficiency and order in the Non-Stop Production line, it is especially preferred in factories and paper processing plants that require high production volume.

How Should Accumulator Maintenance Be?

Maintenance of the Toilet Paper Accumulator is important to ensure long life and efficient operation of the device. The maintenance routine should include the following:

- Regular Cleaning and Lubrication: Necessary for proper operation of the device.

- Inspection of Mechanical Parts: Regular inspection of moving parts.

- Inspection of Electronic Systems: Regular checking of the electronic systems of the device.

Conclusion

The accumulator is a critical transfer machine that increases efficiency and order in toilet paper and kitchen towel roll production lines. With its high storage capacity and automatic sorting features, it ensures that production processes run smoothly and efficiently. With regular maintenance and proper use, this device can serve effectively for many years.