Toilet Paper Cutting Log Saw 2 channels

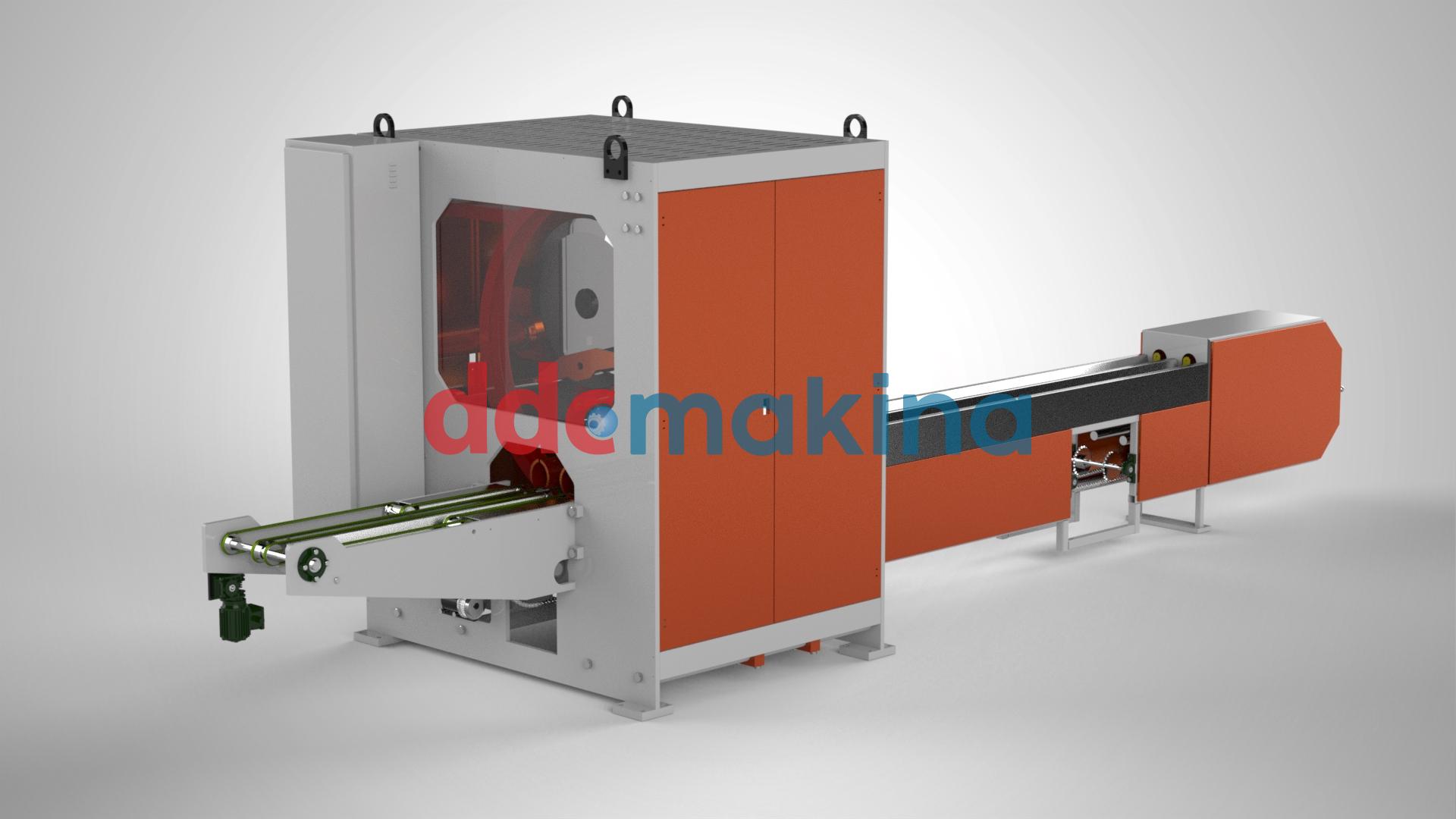

The 2 Channels Log Saw Toilet Paper Cutting Machine is a high capacity industrial machine designed to cut long and continuous toilet paper rolls (logs) according to specified dimensions.

At the present, toilet paper production has become an industry that requires high speed and efficiency. The 2 Channels Log Saw (Toilet Paper Cutting Machine) is a critical part of this process and is an industrial machine with advanced Technology that allows toilet paper rolls (logs) to be cut in standard sizes and with high precision.

By making sharp cuts at high speed, this machine significantly increases both the efficiency of the toilet paper production process and product quality. Moreover, its rapid adaptation to ever-changing market demands makes this machine indispensable for toilet paper production facilities.

What is The 2 Channels Log Saw Toilet Paper Cutting Machine?

The 2 Channels Log Saw Toilet Paper Cutting Machine is a high capacity industrial machine designed to cut long and continuous toilet paper rolls (logs) according to specified dimensions. The most important feature of this machine is its two-channel structure.

Due to this structure, the machine can cut two different rolls at the same time, which significantly increases the speed and capacity of the production process. Especially in large-scale toilet paper production facilities, speed and efficiency are essential and this machine meets exactly this need.

What are The Characteristics of 2 Channels Log Saw Toilet Paper Cutting Machine?

The main features of this machine are:

- High Cutting Speed and Precision: it performs the cutting process extremely quickly and precisely, which increases the speed of the production process and product quality.

- Double Channel Design: having the capacity to cut two different rolls allows more products to be processed at the same time.

- Automatic Adjustment Feature: the automatic adjustment feature for cutting toilet paper rolls of different sizes and thicknesses makes the machine flexible and useful.

- Durability and Solidity: It has a long-lasting and durable structure suitable for continuous and intensive use.

| WORKING TYPE | ORBITAL |

| NUMBER OF CHANNELS | 2 CHANNELS |

| LOGSAW WIDTH | MIN 1350 – MAX 2800 MM |

| BLADE DIAMETER | 610 MM |

| CUTTING DIAMETER | Min 90 – Max 180 MM |

| CUTTING SIZE CONTROL | SERVO CONTROL |

| WORKING CUT PER MIN | 120 (4 ROLLS PER CUT) |

| GRINDING | AUTOMATIC |

| COOLING AND LUBRICATION | AUTOMATIC |

| CUTTING MISTAKE | +/- 1MM |

Where is The 2 Channels Log Saw Toilet Paper Cutting Machine Used?

This machine is especially used in large-scale toilet paper production facilities, paper processing facilities and large companies producing fast-moving consumer goods.

Due to its high production capacity and speed, it is ideal for maximizing efficiency and production speed in such facilities. In addition, its ability to quickly adapt to changing market needs is one of the main reasons why this machine is preferred.

How Should the 2 Channels Log Saw Toilet Paper Cutting Machine be Maintained?

Regular maintenance of this machine is critical to extend its performance and life.

- The Maintenance Routine Should Include the Following Steps: Regular Lubrication and Cleaning: regular lubrication and cleaning is essential for the machine to operate continuously and efficiently.

- Control and Maintenance of Cutter Blades: regular checking of cutter blades and maintaining their sharpness keeps the cutting quality high.

- Moving Parts’ Control: carrying out the necessary maintenance by paying attention to the wear and tear of the moving parts of the machine.

- Testing of Electronic Systems: the machine’s electronic systems have to be tested regularly and adjusted if necessary.

Toilet Paper Cutting Machine With Double Channeled Log Saw Types of Products

- Household Toilet Paper

- Self-pull Toilet Paper

- Jumbo Toilet Paper

- Kitchen Towel

- Internal Pull Towel

- Industrial Towel

- Examination Table Cloth

Conclusion

The 2 Channels Log Saw Toilet Paper Cutting Machine is an industrial machine with a double channel, high speed and precise cutting capacity, which improves the efficiency and quality of the toilet paper production process. This machine, which has an important place in production facilities, can operate efficiently for many years with regular maintenance and correct use.